Get Technical Downloads

Get Technical DownloadsMECHANICALLY FIXED INSULATED

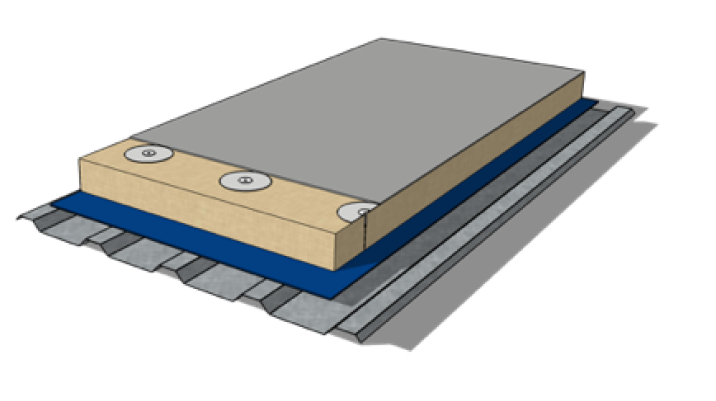

STEEL DECK SYSTEM

SYSTEM OVERVIEW

The Fatra insulated steel deck roof system incorporates the structural steel Fatra Speed Deck as the substrate with the PIR insulation board which is mechanically fixed to the Fatra Speed Deck using the Fatra engineered pad system. Once fixed into place the Fatrafol 810v PVC waterproofing system is attached to the FatraPad system using the engineered Pad adhesive which fuses the Fatrafol PVC membrane to the fixing system creating a none penetrative mechanically fixed system.

The specifications for the Fatra Speed Deck will depend on the clients objectives, requirements and project specific specifications. Fatra provide all components for the steel deck roof projects making it simple and convenient for our approved applicators.

This system is the ideal roofing system for structural steel envelopes and provides the client with superior thermal efficiency and reduced installation programmes compared to traditional metal deck roof systems. All joints, laps and terminations are hot air fusion welded creating a permanent and physical bond and do not rely on adhesives sealants or tapes to create a waterproofed joint.

Fatra provide condensation risk analysis reports for all insulated systems along with a wind load calculation report which dictates the fixing patterns available and a full specification outlining which build up will achieve your project objectives and provide the most sustainable and energy efficient waterproofed system.

FATRAFOL 810v | Reinforced PVC Waterproofing Sheet Membrane

The Fatrafol 810v polyester reinforced membrane is fully bonded to the Fatra PVC pads using Fatrabond pad adhesive. The adhesive bond achieves a 6.4kn uplift strength between the membrane and fixing system.

PIR | Insulation Board

The PIR insulation is installed over FatraPar and mechanically fixed to the Fatra Speed Deck to fully insulate the roof structure. Depending on the R Value requirements various thicknesses of insulation are available.

FATRAPAR | Vapour Control Layer

The Fatrapar vapour control layer is laid over the substrate and is sealed along all laps, joints, penetrations and upturns using double sided butyl tape to prevent moisture ingress.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL