Get Technical Downloads

Get Technical DownloadsBALLASTED UNINSULATED

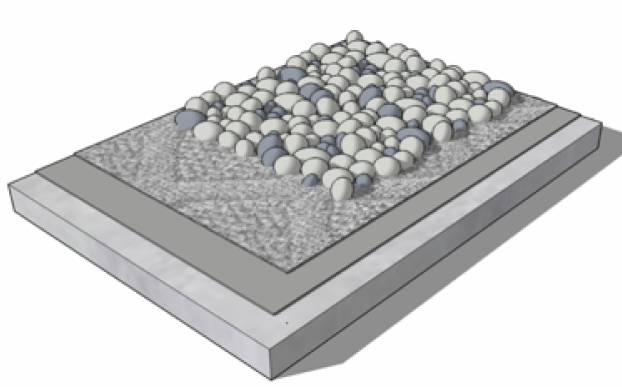

CONCRETE ROOF SYSTEM

SYSTEM OVERVIEW

The Fatra ballasted system can be implemented with a number of different types of ballast such as pebbles, adjustable chairs/pedestals and pavers and floating decks can all be used to ballast the PVC membrane system into place.

Depending on site specific requirements and objectives the membrane can be loose laid, mechanically fixed or even fully adhered making this type of system extremely versatile.

Implementing a ballasted system can reduce material and installation cost depending on the method of application whilst providing protection to the PVC membrane from the harsh UV which will in turn increases the life expectancy of the PVC membrane. By implementing a ballasted system it covers the PVC membrane and can provide a very aesthetically pleasing finish.

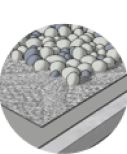

FATRAFOL 810v | Reinforced PVC Waterproofing Sheet Membrane

The Fatrafol 810v is used to form part of a ballasted system. The Fatrafol 810v provides superior cost efficiency from both a material and installation perspective

FATRA ARMOUR | Protection Mat

Fatra Armour protection mat is loose laid over the Fatrafol PVC membrane to protect the membrane from any sharp edges that may be present with the desired ballast.

PEBBLE | Ballast

A pebble ballast, adjustable chair and pavers or a floating deck system is installed over the Fatrafol PVC membrane system to ballast the membrane into place without the requirement to bond or fix the membrane into place.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL