Get Technical Downloads

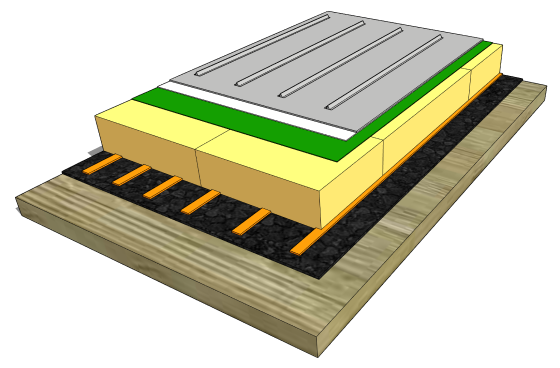

Get Technical DownloadsFULLY ADHERED INSULATED

STANDING SEAM REPLICATE

REFURBISHMENT SYSTEM

SYSTEM OVERVIEW

The Fatra standing seam replicate insulated system is perfect for modern day buildings which provides unrivalled thermal performance and aesthetics for bespoke projects which creates the look of a metal roof but with the performance of Fatra PVC membrane system.

The system consists of the FatraVap self adhered vapour control layer bonded directly to the substrate to prevent any condensation ingress. The PIR insulation board is then full bonded directly to the FatraVap using the Fatrabond insulation adhesive. Once the insulation is bonded into place the Fatrafol 807v PVC membrane is then fully adhered to the tissue faced insulation board using the Fatrabond 1215 moisture curing polyurethane adhesive to create a fully adhered insulated roof system. The standing seam replicates are then hot air fusion welded to the field sheet membrane at identical centres to achieve the look of a traditional metal deck roof. The standing seam replicates come in lengths of 3m to reduce the amount of setting out required.

The Fatra standing seam replicate system is the perfect solution for almost any roof where aesthetics and performance are the number one priority. Unlike traditional metal deck roofs, the Fatra standing seam replicate system comes with an array of accessories to create a fully homogenous system that does not require onsite fabrication or is reliant on silicone seals along the joints and laps. The Fatra standing seam system is fully hot air fusion welded creating a permanent waterproofing system with a life expectancy in excess of 30 years.

STANDING SEAM REPLICATE | PVC Standing Seam Profiles

Fatra PVC standing seam replicates are hot air fusion welded to the Fatra PVC membrane to provide the look of a metal roof system with the performance of a PVC membrane system.

FATRAFOL 807v | FLEECE BACK PVC MEMBRANE

The Fatrafol 807v fleece back membrane is fully adhered directly to the PIR tissue faced insulation board with the Fatrabond 1215 moisture curing polyurethane adhesive.

PIR | INSULATION BOARD

The PIR insulation is installed over the vapour control and is fully adhered using Fatrabond 1210 moisture curing polyurethane adhesive

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL