Get Technical Downloads

Get Technical DownloadsFULLY ADHERED LIQUID REFURBISHMENT

SYSTEM OVERVIEW

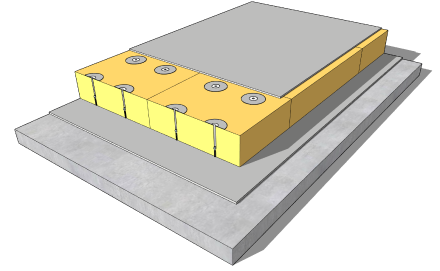

The Fatra mechanically fixed insulated roof system has been specifically engineered by Fatra to create a non-penetrative mechanically fixed insulated system. This system provides the client with superior thermal efficiency, reduced installation programmes, reduced material costs and can reduce air conditioning costs by up to 25% per annum.

Depending on the condition of the existing membrane and a condensation risk analysis report, this system can be installed directly over the existing failed membrane substantially reducing the overall project costs and risks associated with removing existing membranes and exposing the existing structure to water damage during this process.

As building standards evolve and change over time, many existing structures are likely to be insufficiently insulated or in some cases not insulated at all. By implementing a Fatra insulated system not only does it provide the client with a more comfortable living or working environment but can bring the building up to todays standards.

Traditional membrane systems require ballast to weight down the insulation which is placed on top of the membrane where as the Fatrapad system fastens the insulation to the roof area in accordance with AS1170.2 meaning you can be secure and confident that this solution is designed to your needs.

The Fatra systems are hot air fusion welded along all joints, laps and terminations creating a permanent and physical bond and does not rely on adhesives, sealants or tapes to create a waterproofed joint making it the most durable and reliable waterproofing system on the market.

FATRAFOL 810v | REINFORCED PVC SHEET MEMBRANE

The Fatrafol 810v reinforced membrane is installed over the PIR insulation. The Fatrafol 810v is bonded to Fatra Australia's uniquely engineered Pad system which is fused to the fixing system creating a none penetrative mechanically fixed system.

PIR INSULATION | FOIL FACED INSULATION BOARD

The PIR insulation is installed over the existing failed membrane and is mechanically fixed using approved fixings and telescopic tubes. The FatraPad system is secured to the structure in accordance with AS1170 Part 2.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL