Get Technical Downloads

Get Technical DownloadsFULLY ADHERED INSULATED

LIQUID REFURBISHMENT

SYSTEM OVERVIEW

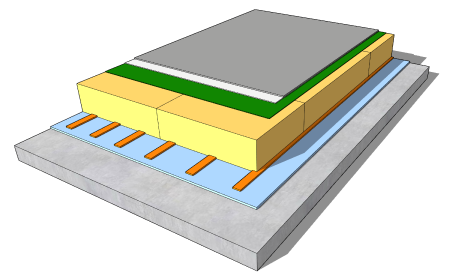

The Fatra fully adhered insulated roof system is a completely none penetrating fully adhered membrane system. This system provides the client with the most thermally efficient insulated system due to there being zero thermal bridges within the system and its components. Depending on the condition of the existing membrane and a condensation risk analysis report, this system can be installed directly over the existing failed membrane substantially reducing the overall project costs and risks associated with removing existing membranes.

As building standards evolve and change over time, many existing structures are likely to be insufficiently insulated or in some cases not insulated at all. By implementing a Fatra insulated system not only does it provide the client with a more comfortable living or working environment but can bring the building up to todays standards.

All joints, laps and terminations are hot air fusion welded creating a permanent and physical bond and does not rely on adhesives sealants or tapes to create a waterproofed joint.

Implementing a tissue faced insulation board and the Fatrafol 807v fleece back membrane the number of fixings required to complete the system are minimised making it the perfect solution for live environment projects.

FATRAFOL 807v | FLEECE BACK PVC SHEET MEMBRANE

The Fatrafol 807v has a fleece backing which enables the PVC membrane to be fully adhered directly to the PIR tissue faced insulation board using the Fatrabond 1215 moisture curing polyurethane adhesive.

PIR Insulation | TISSUE FACED INSULATION BOARD

The PIR by Fatra insulation is fully adhered over the existing failed membrane using Fatrabond 1210 insulation adhesive to bond the insulation into place.

FATRABOND 1210 | MOISTURE CURING ADHESIVE

The Fatrabond 1210 insulation adhesive is used to fully adhere the PIR insulation directly to the existing membrane. The Fatrabond adhesive is unaffected by the substrate moisture or inclement weather improving productivity and reducing overall installation programmes.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL