Get Technical Downloads

Get Technical DownloadsBALLASTED BITUMEN REFURBISHMENT

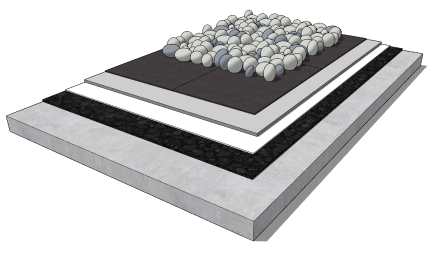

SYSTEM OVERVIEW

The Fatra ballasted system can be implemented with a number of different types of ballast. Including pebbles, adjustable chairs/pedestals and pavers or even a floating timber deck can be used to ballast the PVC membrane system into place.

Depending on site specific requirements and objectives the membrane can be loose laid or mechanically fixed over the existing failed membrane which substantially reduces the overall project costs and risks associated with removing existing membranes and exposing the existing structure to water damage during this process.

Implementing a ballasted system can reduce cost depending on the method of application whilst providing protection to the PVC membrane from the harsh UV which will in-turn increase its life expectancy. In turn ballasted systems can provide an aesthetically pleasing finish.

FATRA ARMOUR | PROTECTION MAT

The Fatra Armour protection mat is installed directly over the PVC membrane to provide protection to the waterproofing system from any sharp edges and pertruding items which might be present in the desired ballast.

FATRAFOL 810v | REINFORCED PVC SHEET MEMBRANE

The Fatrafol 810v reinforced membrane is installed over the FatraTex geotextile protection layer. The Fatrafol 810v is loose laid over the protection layer and is ballasted into place by the desired ballast.

GEOTEXTILE | FABRIC

FatraTex geo-textile fabric is loose laid over the existing failed membrane to provide protection to the Fatrafol PVC membrane from any potential contaminants which maybe present in the existing membrane.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL