Get Technical Downloads

Get Technical DownloadsFULLY ADHERED INTERNAL WET AREA

REFURBISHMENT SYSTEM

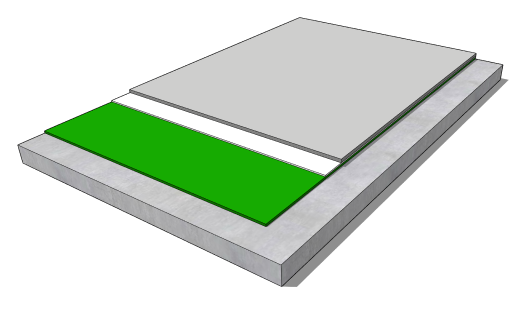

SYSTEM OVERVIEW

Depending on the condition of the existing membrane, this system can be installed directly over the existing failed membrane, substantially reducing the overall project costs and risks associated with removing existing membranes and exposing the existing structure to water damage during this process.

The Fatra fully adhered system is bonded directly over the existing system using the Fatrabond moisture curing polyurethane adhesive. The Fatrafol 807v has a 180gsm fleece backing which provides protection to the Fatrafol membrane from any potential contaminants in the existing failed membrane.

Unlike traditional liquid applied systems which require extensive preparation and are affected by numerous variables such as substrate moisture content, an average of 24 hour cure times per coat and inclement weather the Fatrafol PVC membrane system performance and reliability is not affected by any of these issues which cause liquid membranes to fail so often. As the Fatrafol PVC membrane system is a sheet membrane, overlaying finishes can be installed once the installation is complete and signed off.

The Fatra fully adhered system is unaffected by substrate moisture and inclement weather conditions during installation, unlike liquid applied membranes which can delaminate & defect prematurely should the substrate have a high level of moisture content. All joints, laps and terminations are hot air fusion welded creating a permanent and physical bond and does not rely on adhesives sealants or tapes to create a waterproofed joint. The Fatrafol 807v provides unrivalled shear and tear resistance so should the system ever be exposed to structural cracking or excessive structural movement, the Fatrafol membrane will remain intact making it the perfect internal wet area waterproofing system.

FATRAFOL 807 | FLEECE BACK PVC SHEET MEMBRANE

The Fatrafol 807 has a 180gsm fleece backing which enables the PVC membrane to be fully adhered directly to the substrate using the Fatrabond 1215 moisture curing adhesive.

FATRABOND 1215 | MOISTURE CURING ADHESIVE

The Fatrabond 1215 moisture curing polyurethane adhesive is used the bonded the Fatrafol 807 v PVC membrane directly to the substrate. The Fatrabond adhesive is unaffected by the substrate moisture or inclement weather improving productivity and reducing overall installation programmes.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL