Get Technical Downloads

Get Technical DownloadsUNINSULATED PVC COATED

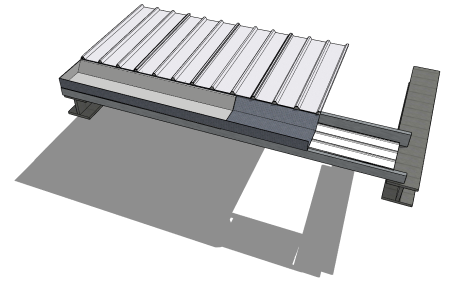

BOX GUTTER REPLACEMENT

SYSTEM OVERVIEW

The Fatra refurbishment box gutter system implements the Fatrafol 810v PVC membrane which is bonded to the existing box gutter which provides a fully waterproofed system without having to remove the existing box gutter.

The Fatra box gutter refurbishment system drastically reduces overall project costs and programming and provides an additional 30 years life expectancy to the existing box gutter. All joints, stop ends and drainage points in the gutter are hot air fusion welded and various prefabricated accessories are available to create a permanent and homogeneous waterproofed system.

FATRAFOL 810v | REINFORCED PVC SHEET MEMBRANE

The Fatrafol 810v reinforced membrane is installed over the existing box gutter and is bonded into place using the Fatrabond Contact adhesive. Prefabricated outlets and accessories are used to create a fully integrated PVC membrane box gutter system.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL