Get Technical Downloads

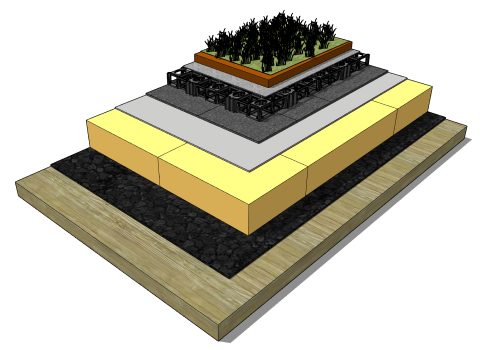

Get Technical DownloadsBALLASTED INSULATED

BITUMEN GREEN

ROOF REFURBISHMENT

SYSTEM OVERVIEW

The Fatra insulated green roof system incorporates the PIR insulation board below the Fatrafol PVC membrane waterproofing system with the Fatra Armour protection layer, Fatra drainage cell, filter fabric and vegetation layer to create the perfect green roof system. This system is simply installed directly over the existing failed membrane.

The specifications for the different layers will depend on the clients objectives, requirements and project specific specifications.

Fatra provide all components for green roof projects making it simple and convenient for our approved contractors.

The Fatrafol PVC membranes are tested to FLL standards and are proven to withstand root penetration from the most aggressive roots such as birch and oak trees. No additional protection layers or root resistant coatings are required unlike traditional bitumen and liquid membranes.

Fatrafol membranes are 100% recyclable and can be made using up to 30% recycled materials making Fatra waterproofing membranes the most sustainable and environmentally friendly waterproofing membranes on the market today.

GREEN ROOF | OVERLAYING FINISHES

Fatra Armour protection mat is loose laid over the Fatrafol PVC Membrane to protect the membrane from the drainage cell. Installation of Fatra Drainage cell is then installed with a filter fabric applied above the drainage cell prior to the installation of the green roof build up.

FATRAFOL 810v | REINFORCED PVC SHEET MEMBRANE

The Fatrafol 810v reinforced membrane is installed over the PIR insulation. The Fatrafol 810v is ballasted into place with the green roof build installed above

PIR INSULATION | FOIL FACED INSULATION BOARD

The PIR insulation is installed over the existing failed membrane and is ballasted into place with the green build up which is installed above the Fatra system.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL