Get Technical Downloads

Get Technical DownloadsFULLY ADHERED

COLD STORE PANEL

REFURBISHMENT

SYSTEM OVERVIEW

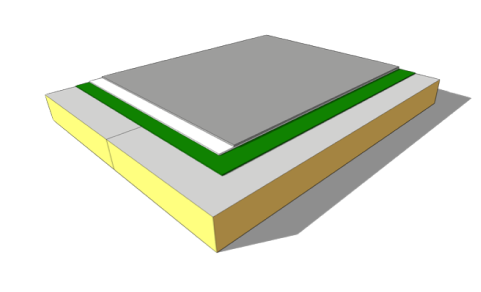

The Fatra cold store insulated roof panel refurbishment system provides a fully adhered system which is bonded directly the exisiting roof panel using the Fatrabond moisture curing polyurethane adhesive. A full assessment by a Fatra Australia representative is require to assess the condition of the existing roof panel substrate to ensure adequate adhesion can be achieved and what preparation maybe required such as rust repair, air sealing and other factors that will achieve the best possible performance. A structural assessment maybe required to be carried out by an approved and certified structural engineer to ensure the roof panel and structure are able to carry the additional weight of the Fatra system.

Unlike liquid applied membranes, the Fatrafol 807v is unaffected by substrate moisture and inclement weather conditions during installation which can cause the membrane to delaminate & defect prematurely. All joints, laps and terminations are hot air fusion welded creating a permanent and physical bond and does not rely on adhesives sealants or tapes to create a waterproofed joint.

The fully adhered system improves drainage, the overall aesthetics of the roof system due to not being exposed to a certain amount of wind flutter and also reduces disruption to the client.

Insulated roof panels are constantly exposed to excessive structural movement, the Fatrafol PVC membrane has the ability to move with the roof panels without causing the membrane to shear and tear unlike liquid applied systems which fail along the joints of the roof panel causing water to be absorbed in the roof panel core and potentially the internal building envelope.

FATRAFOL 807v | FLEECE BACK PVC SHEET MEMBRANE

The Fatrafol 807v has a 120gsm fleece backing which enables the PVC membrane to be fully adhered directly to the substrate without any primers or extensive preparation.

FATRABOND 1215 | MOISTURE CURING ADHESIVE

The Fatrabond 1215 moisture curing polyurethane adhesive is used to bond the Fatrafol 807v PVC membrane directly to the substrate. The Fatrabond adhesive is unaffected by the substrate moisture or inclement weather improving productivity and reducing overall installation programmes.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL