Get Technical Downloads

Get Technical DownloadsRETENTION TANK LIQUID

REFURBISHMENT

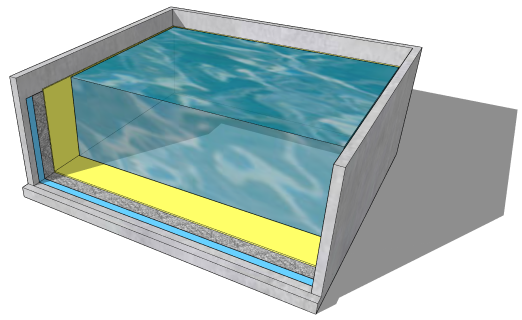

SYSTEM OVERVIEW

The Fatra retention tank refurbishment system provides unrivalled performance when installed in a water storage tank environment. The Fatrafol 803vs is designed to create a full bladder system and can withstand continuous stagnant water without failing or delaminating prematurely. The Fatrafol 803vs gives the client the opportunity to install the membrane over the existing failed membrane depending on the condition of the existing membrane which drastically reduces the cost and program of the project.

Unlike traditional liquid applied systems which require extensive preparation and are affected by numerous variables such as substrate moisture content, an average of 24 hour cure times per coat and inclement weather the Fatrafol Pvc membrane system performance and reliability is not affected by any of these issues which cause liquid membranes to fail so often. As the Fatrafol PVC membrane system is a sheet membrane, overlaying finishes can be installed once the installation is complete and signed off.

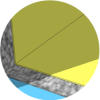

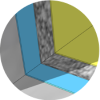

The Fatrafol 803vs is designed to withstand aggressive water pressure, hydrostatic pressure and creates a radon barrier to prevent the natural gases that are present below ground from entering the building foundations. The Fatrafol 803vs is made with a black scrim below and a top yellow signal layer to enable contractors to easily identify any breaches in the membrane. If the yellow top layer is damaged the black scrim layer below shows through making any defects easy to spot and patch repair prior to filling the retention tank. The Fatrafol retention tank system is completely hot air fusion welded which doesn't rely on tapes or sealants to prevent water ingress. The membrane is mechanically fixed and can be installed over almost any substrate with minimal preparation.

FATRAFOL 803VS | Yellow/Black PVC Waterproofing Sheet Membrane

The Fatrafol 803vs is a yellow face/black scrim PVC sheet membrane which is resistant to aggressive water pressure and gasses which occur naturally below ground. The Fatrafol 803vs is fully hot air fusion welded along all joints, laps and terminations meaning it is not reliant on adhesives, sealants or tapes to provide its waterproofing integrity and can be installed directly over the existing failed membrane

GEOTEXTILE | FABRIC

FatraTex geo-textile fabric is loose laid over the existing failed membrane to provide protection to the Fatrafol PVC membrane from any potential contaminants which maybe present in the existing membrane.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL