Get Technical Downloads

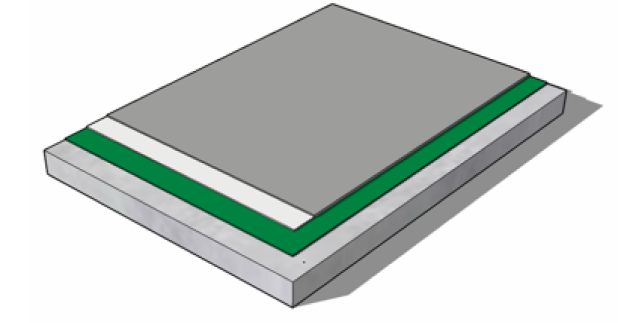

Get Technical DownloadsFULLY ADHERED INTERNAL

WET AREA SYSTEM

SYSTEM OVERVIEW

The Fatra internal wet area waterproofing system implements the Fatrafol 807v fleece back PVC Membrane fully adhered directly to the substrate using the Fatrabond 1215 moisture curing polyurethane adhesive.

The Fatra internal wet area system comes with fully integrated ancillaries and accessories such as drainage outlets, compatible liquid membranes for shower and vanity walls and PVC coated termination angles to provide a fully homogenous waterproofing system.

The Fatrafol PVC membrane is a consistent sheet membrane system unaffected by substrate moisture and requires no drying time resulting in overlaying finishes being installed as soon as the installation has been completed unlike liquid applied systems which should be applied over several days and requires specific drying times depending on site conditions.

The Fatra internal wet area system can drastically reduce the installation and programming times and substantially reduce the risk of premature defects compared to a liquid applied system.

FATRAFOL 807v | Fleece Back PVC Waterproofing Sheet Membrane

The Fatrafol 807v has a 120gsm fleece backing which enables the PVC membrane to be fully adhered directly to the substrate without any primers or extensive preparation.

FATRABOND 1215 | Moisture Curing Polyurethane Adhesive

The Fatrabond 1215 moisture curing polyurethane adhesive is used to bond the Fatrafol 807v PVC membrane directly to the substrate. The Fatrabond 1215 adhesive is unaffected by substrate moisture improving productivity and reducing overall installation programme.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL