Get Technical Downloads

Get Technical DownloadsFULLY ADHERED TAPERED

INSULATED ROOF SYSTEM

SYSTEM OVERVIEW

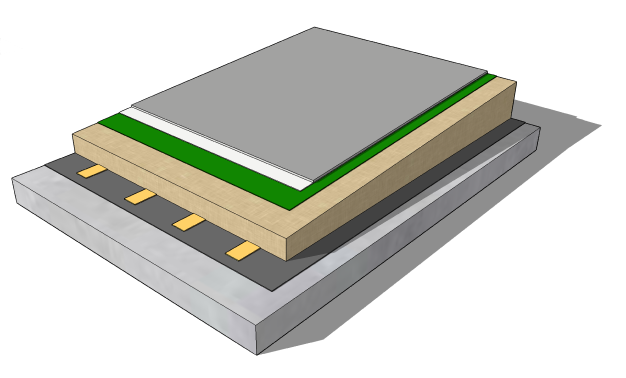

Fatra tapered insulated system consists of the FatraVap self adhered vapour control layer bonded directly to the substrate to prevent any condensation ingress. The project specific designed tapered insulation board is then fully bonded directly to the FatraVap using the Fatrabond insulation adhesive. Once the insulation is bonded into place the Fatrafol 807v PVC membrane is then fully adhered to the tissue faced tapered insulation board using the Fatrabond 1215 moisture curing polyurethane adhesive to create a fully adhered tapered insulated roof system.

The Fatra tapered systems create the fall within the structure with a 99% degree of accuracy. The tapered systems are specifically designed by Fatra for each individual project to accurately drain rainwater to the outlets whilst providing superior thermal performance.

The Fatra tapered insulated systems can be designed and manufactured to create any degree of fall in any direction drastically reducing materials and labour costs compared to creating a fall within a concrete slab.

FATRAFOL 807v | Fleece Back PVC Waterproofing Sheet Membrane

The Fatrafol 807v has a 120gsm fleece backing which enables the PVC membrane to be fully adhered to the insulation board using the Fatrabond 1215 moisture curing polyurethane adhesive.

PIR | Tapered Insulation Board

The PIR tapered insulation board is manufactured to site specific requirements which creates the desired falls in the insulation whilst providing thermal protection and reducing installation and material costs. PIR insulation is installed over the vapour control layer and is completely fully adhered.

FATRAVAP | Vapour Control Layer

The FatraVap vapour control layer is a self adhered vapour barrier which is fully bonded directly to the substrate to protect the structure from condensation.

DOWNLOADS

GET ALL FILES IN EMAIL

WORD SPEC

WORD SPEC CAD DETAILS

CAD DETAILS 2D DRAWINGS

2D DRAWINGS INSTALL GUIDE

INSTALL GUIDE TECH DATA SHEETS

TECH DATA SHEETS MAINTENANCE

MAINTENANCE 3D TECH SPEC

3D TECH SPEC CERTIFICATION

CERTIFICATION

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL