Removing Project Headaches via Innovative Design

Tapered Insulation & where to use it

Karl Chiverton

10th December 2020

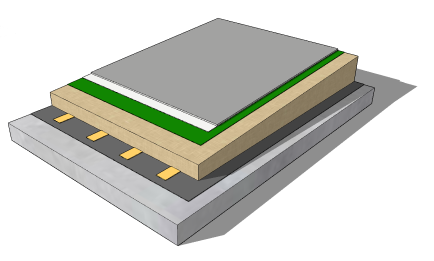

Cut to fall insulation is factory produced insulation with accuracy of less than 1mm. This type of insulation is predominantly used over concrete and timber roof structures as part of a built up PVC membrane system as shown below

The Cost Debate

Rightly so, cost and budgets are at the forefront of every builders’ mind. Thats why the following should be considered when choosing a system:

- Hidden Costs - More often than not, it’s the additional hidden costs with certain systems that inevitably mount up, sending the project hugely over budget. Fatra tapered insulated systems are unique in the sense that the initial costings will be higher but without these hidden costs, often works out the most cost effective solution. Our innovative process will change the way you budget your projects.

- Programme Benefits - Inefficient programming is the silent killer of all budgets. Setup and weekly running costs in construction are extremely high, making the completion of projects quickly and efficiently very important. Fatra’s systems are designed in a way to reduce the program length, enabling you to move on to the next money making project. Concrete slabs take 21 days to cure before you can apply an adhered waterproofing membrane such as a liquid or spray system. Fatra insulated systems can be installed as soon as you can get a correct fixing hold into the slab determined by site specific pull out testing.

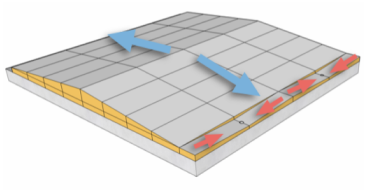

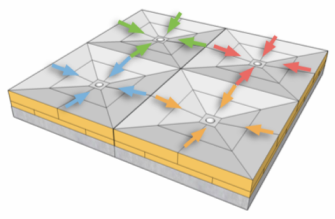

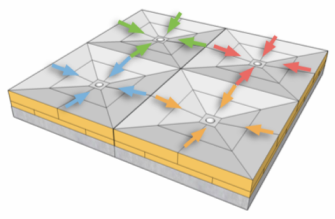

- Guaranteed Falls - Fatra create site specific tapered insulation plans which are bespoke to suit your project. Ensuring the correct compliant falls are pinpoint manufactured, so you do not have to deal with fall related compliance issues and defects in the waterproofing membrane. As we know, the reliability of falling concrete or screed to achieve compliant falls is not always simple, making it a timely and costly exercise. Fatra systems remove the potential for human error, ensuring a smooth process.

- Pinpoint Electronic leak detection - Fatra insulation is lined with conductive foil providing a surface for simple pinpoint electronic leak detection. This protects the internal of your building saving potentially costly defects later on.

Safety & Eliminating Defects

- Safety - Installing insulation above a rooftop is a much simpler exercise than attempting to insulate from the underside of a slab. Under slab insulation installs will often have to be carried out via the use of an elevated work platform, these have been the cause of multiple deaths across the Australian construction industry. Protect the people and protect yourself.

- Fire Performance - Fire is a Hot Topic in the Australian construction industry since the Grenfell disaster in the UK. You can rest assured knowing that Fatra Insulated Roofing Systems come with FM Approvals and B Roof compliance testing. These are independent leaders in third party testing, carrying out by far the most rigorous fire testing to the roofing system as a whole, making Fatra Systems amongst the flag bearers in fire performance worldwide.

- Condensation Issues - Insulating a roof from the underside means heat is transferred into the building before it is cooled creating an environment for internal condensation. This is obviously a huge issue and something you would avoid with the Fatra tapered roof system.

- Air Leakage - The Rapid changes in construction codes call for Zero air leakage. Fatra Insulated systems provide this and will comfortably pass any form of smoke and air leakage testing through air sealed details.

- Section J Compliance - All Fatra insulated systems are specifically designed to encapsulate the section J requirements for your rooftops. With the new changes to the BCA code that came into effect in May 2020, Fatra PVC insulated system will make $$$$ sense even against lower grade and cheaper systems. The new thermal bridging requirements will essentially make under slab insulation obsolete.

Ethical & Sustainable Values

Fatra PVC membrane systems are the most sustainable roofing and structural waterproofing systems in the market today taking into consideration:

- Lower Energy Costs - Fatra thermally insulated systems can achieve pretty much any insulation R Value that you want to achieve. This in turn lowers your energy costs and brings a lower CARBON FOOTPRINT to your build.

- Recyclable - Fatra PVC membrane systems are fully recyclable at the end of their service life. Fatra have invested 14 Million euros into a state-of-the-art recycling facility in which all waste created during production is re added back into production creating a ZERO WASTE production system.

- Sustainability - Even at 1.2mm thickness, Fatra membranes are backed by independent bodies to last in excess of 30 years, whilst many other products are struggling to even get out of there builders warranty periods before defecting. The initial cost of Fatra membranes against the REAL cost over the service life of a membrane is incomparable.

Here are just some of the many benefits to a Fatra Tapered Insulated roof, if you would like to see if this could be the right solution for your next project please get in touch.

OVERVIEW

OVERVIEW PROJECT BUILDER

PROJECT BUILDER PARTNER NETWORK

PARTNER NETWORK ORDER ONLINE

ORDER ONLINE ESTIMATION TOOL

ESTIMATION TOOL